Feature of Yellow Sandstone

L'attrait esthétique :

The vivid yellow hue of yellow sandstone gives any area coziness and visual intrigue. It has an inherent beauty that can improve the overall aesthetics of designs, both external and interior.

Polyvalence :

Yellow sandstone is a material that works well in a variety of settings. It can be sculpted and cut into a variety of sizes and shapes, which makes it appropriate for decorative components, wall cladding, flooring, and building facades.

Durabilité :

Sandstone is renowned for its durability, and yellow sandstone is no exception. It may be used both indoors and outdoors because of its resistance to weathering, erosion, and natural forces. Yellow sandstone with proper care can last for many years and still be beautiful.

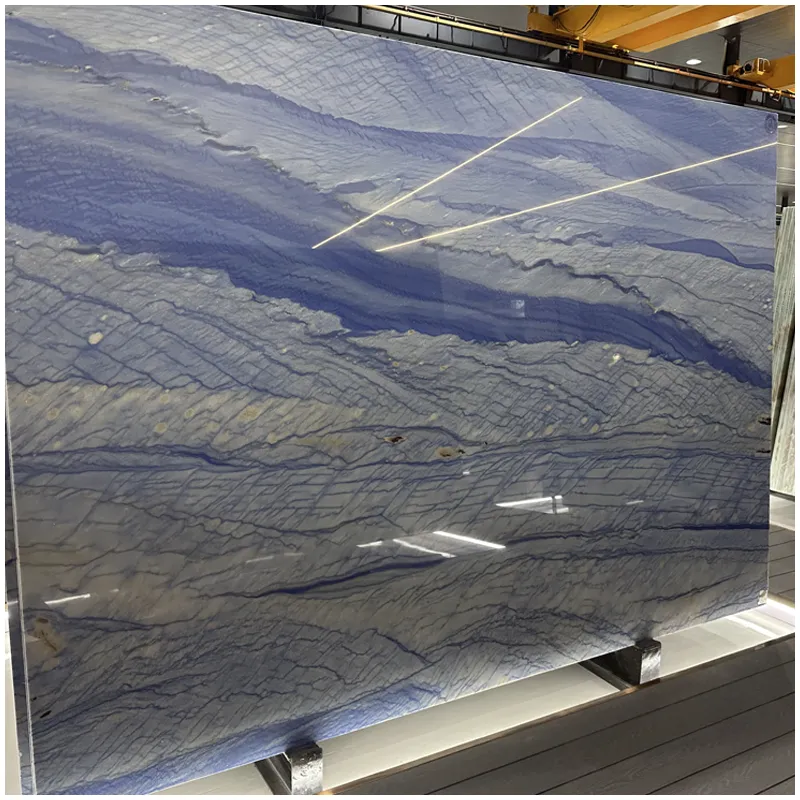

Natural and Unique Patterns:

The deposition and compression of sand grains produce intriguing patterns and textures that are frequently seen in yellow sandstone. These organic variances give each project personality and a distinctive, eye-catching appearance.

Résistance à la chaleur :

Sandstone exhibits exceptional thermal resistance, rendering it a favorable option for regions experiencing significant fluctuations in temperature. Its ability to withstand heat and sustain a pleasant surface temperature makes it ideal for outdoor and flooring applications.

Disponibilité :

Due to its widespread availability across the globe, yellow sandstone can be used for a variety of building and architectural projects. When compared to rare or exotic stone types, this availability can make procurement more straightforward and cost-effective.

The Manufacturing Process Of Yellow Sandstone

Quarrying:

The first step in the procedure is to remove the yellow sandstone from the ground. Using massive gear and tools, large blocks or slabs of sandstone are removed from the quarry site during the quarrying process. Depending on the particular quarry and the geological conditions, the site and technique of quarrying may change.

Cutting and Shaping:

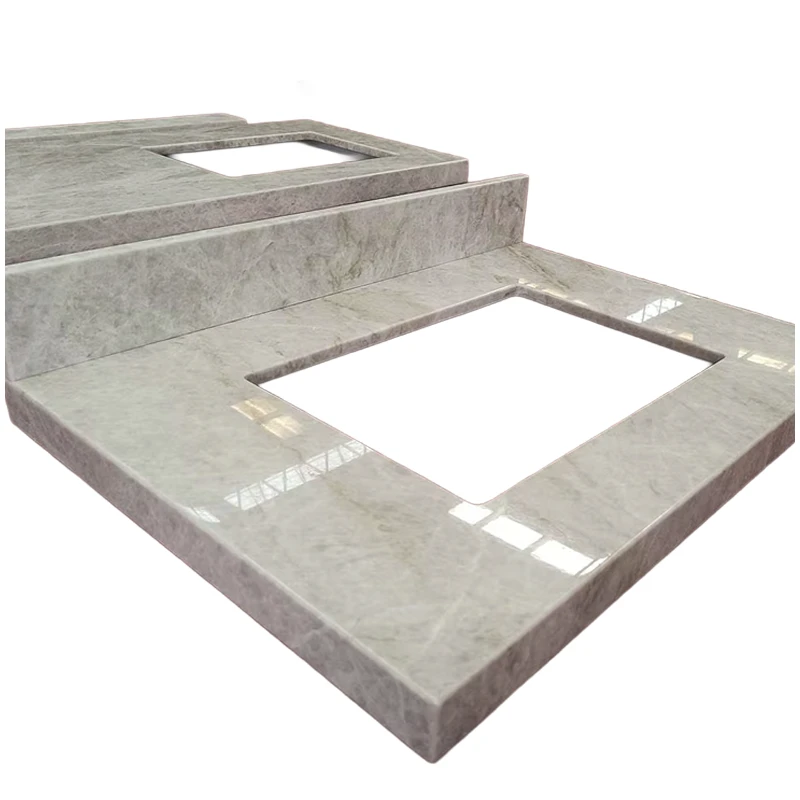

After being mined, the yellow sandstone blocks are taken to a processing plant where they are shaped and cut into smaller pieces in accordance with their intended usage. Saws, diamond wire saws, and other cutting tools can be used for this. Depending on the intended use, the stones may be carved into slabs, tiles, or other shapes.

Finition de la surface :

To get the right texture and look, yellow sandstone can go through a number of surface finishing procedures. Sandstone’s surface can be polished, honed, brushed, bush-hammered, or have a natural cleft finish. These finishes are produced with methods like chiseling, polishing, brushing, and grinding.

Inspection and Quality Control:

The yellow sandstone is examined for quality control reasons at various stages of the manufacturing process. In order to do this, look for any flaws, cracks, or variations in size, texture, or color. Stones that don’t fit the quality requirements can be recycled or thrown away.

Packaging and Distribution:

Following processing and inspection, yellow sandstone is usually packaged and ready for delivery. To keep the stones safe during transit, they can be crated, palletized, or wrapped. After that, they are sent to vendors, merchants, or clients so they can be used for landscaping, building, or other purposes.

Dimensions of Yellow Sandstones

Natural Yellow Sandstone | |

Taille | 8*36mm,7*36mm, 8*36mm,9*36mm, |

Détail de l'emballage | 1) Dalle : plastique à l'intérieur + paquet de bois résistant à la mer à l'extérieur |

2) Tuile : mousse à l'intérieur + caisses en bois solides et résistantes à la mer avec des sangles renforcées à l'extérieur. | |

3) Comptoir : mousse à l'intérieur + caisses en bois solides et résistantes à la mer avec des sangles renforcées à l'extérieur. | |

Assurance qualité : Tout au long du processus de production, du choix des matériaux à l'emballage en passant par la fabrication, notre personnel chargé de l'assurance qualité contrôle rigoureusement chaque processus afin de garantir le respect des normes de qualité et la ponctualité des livraisons. | |

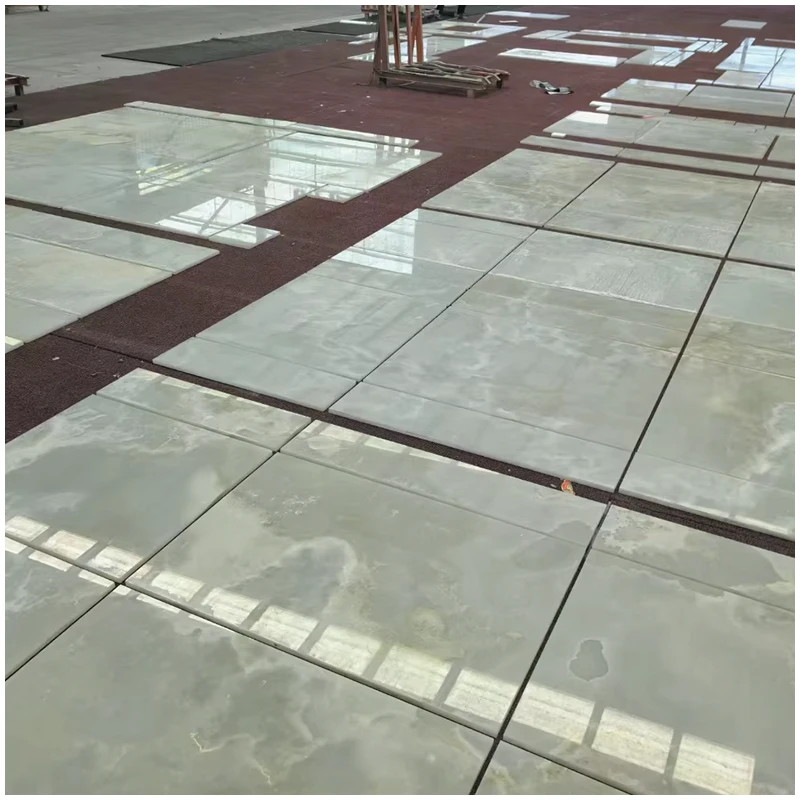

Application of Yellow Sandstone

Yellow sandstone finds wide application in various architectural, construction, and landscaping projects due to its aesthetic appeal, durability, and versatility. Construction Facades: Yellow sandstone is a common cladding material for facades. Whether applied to residential, commercial, or historical landmarks, its warm golden tone gives them an exquisite, timeless appearance. Revêtement de sol : Because of its natural beauty and longevity, yellow sandstone is a great option for flooring. It can be utilized in living rooms, patios, corridors, and outdoor walks, among other indoor and outdoor settings. Sandstone’s rough surface gives the flooring good traction and a touch of rustic character. Paving: Driveways, paving, courtyards, and garden paths are among the outdoor spaces that frequently include yellow sandstone paving. It is appropriate for high-traffic locations due to its resilience to weathering and sturdy character. |  |

| Revêtement mural : The visually pleasing and textured surface of yellow sandstone can be applied to both internal and outdoor walls. It can be used to improve a building’s architectural character as individual stone veneers or as piled stones. Aménagement paysager : Yellow sandstone is frequently utilized in landscaping projects. It can be used to build steps, garden walls, retaining walls, and ornamental elements like sculptures or fountains. Its natural tint creates a calming, earthy atmosphere when combined with the outdoor environment. Decorative Elements: Columns, balusters, arches, and moldings are just a few of the ornamental features that can be carved or molded out of yellow sandstone. These can be applied to produce a distinctive style statement and accentuate the architectural details. Monuments et mémoriaux : For millennia, monuments and memorials have been built using yellow sandstone. It is appropriate for commemorating significant events or honoring historical personalities due of its resilience to weathering. |

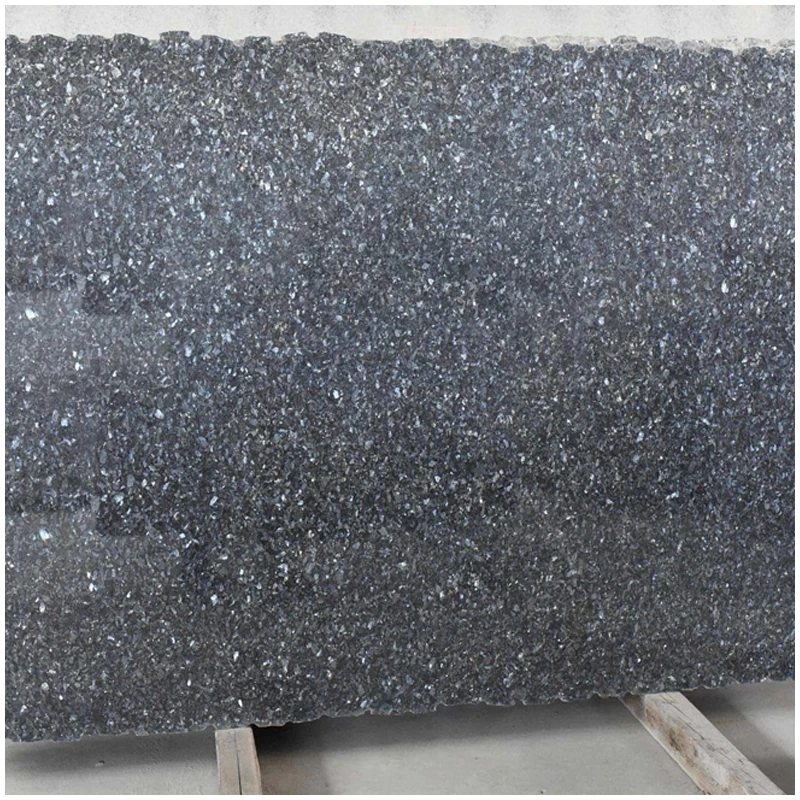

Yellow Sandstones Factory

Maintance Of Yellow Sandstones

Proper maintenance of yellow sandstone is essential to preserve its appearance and durability over time.

Protection from Physical Damage:

Take care to shield the yellow sandstone from harm. To prevent chips, cracks, or scratches on the stone surface, do not move furniture or dump large objects directly onto it. To keep furniture legs from making direct touch with the stone, place coasters or protective mats underneath them.

Inspections fréquentes :

Check the yellow sandstone on a regular basis for indications of wear and tear, such as chips, cracks, or loose sections. Deal with any problems as soon as possible to stop more harm or degradation. If repairs or restorations are required, speak with a qualified stone restoration specialist.