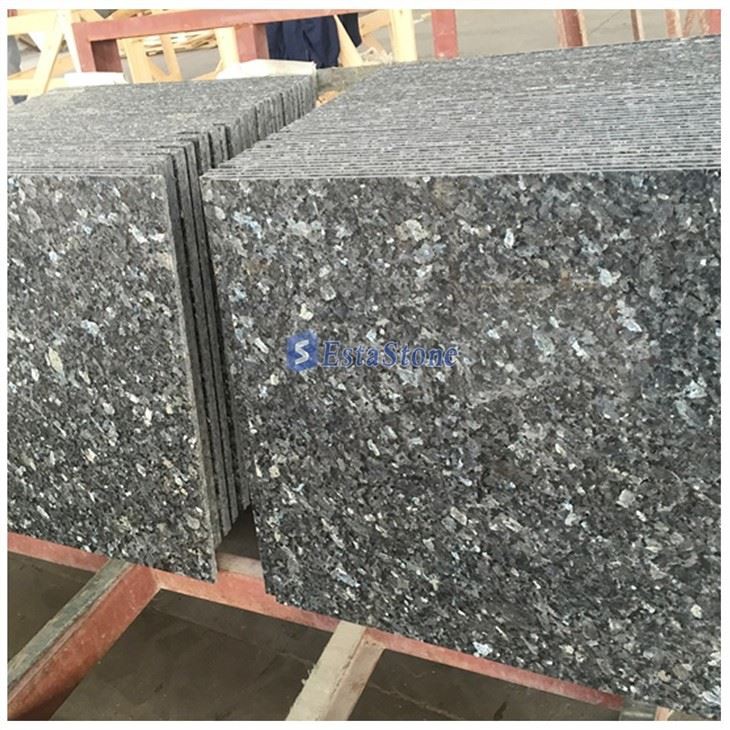

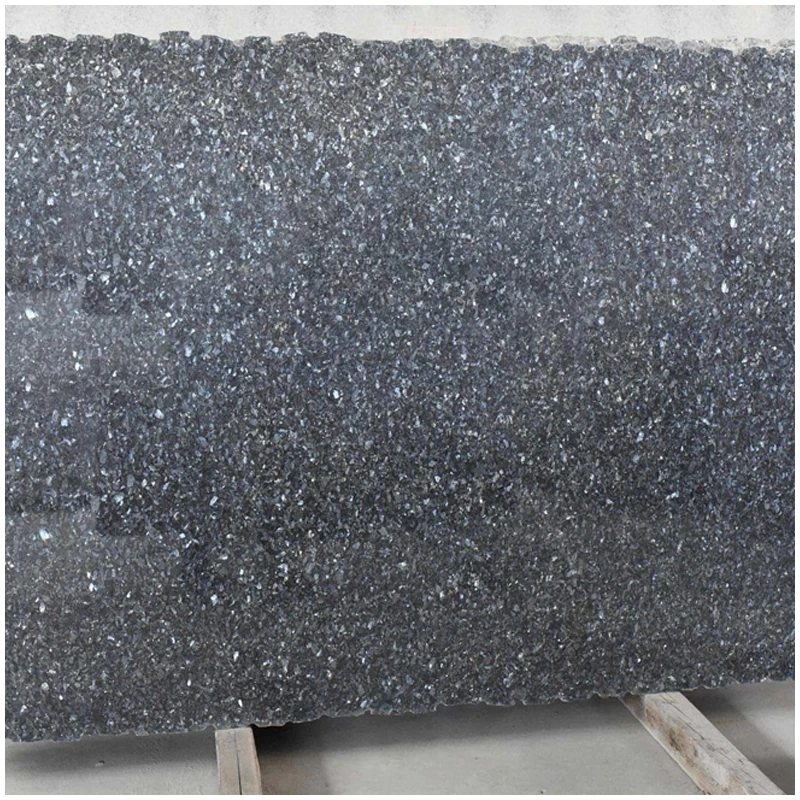

Polished Blue Pearl Granite Floor and Wall Paving Tiles For Interior Projects

The beautiful crystals within a Blue Pearl Granite would be totally wasted without a finish that highlights these stunning specks. This tile has a polished finish, created by buffing a smoothed down stone continually. It's a laborious process that can remove up to 1mm of the tile's surface in order to create a mirror-shine finish.

Blue Pearl Granite is also commercially known as Labradorite Blue. The fairly uniform Blue Pearl Granite Floor Tiles is used for interior well as exterior purposes like flooring, cladding, and counters. It is a coarse-grained, light blue Labradorite stone, chiefly consisting of alkali feldspar. Its sawing direction is vein cut and water absorption is 0.11%.

Blue Pearl granite from Norway features shades of blues, grays, and some beige. This durable granite is good for commercial and residential products and is an exceptional option for the cladding exterior walls.

Blue Pearl Granite Floor Tiles are one of the best searchable and demanded products and as per high customer demand of this product. This is available in different shapes and sizes. The splendid color and tough durability make this blue pearl granite a favorite of many.

크기 | 타일 크기: 305x305mm 또는 12"x12" 400x400mm 또는 16"x16" 457x457mm 또는 18"x18" 600x600mm 또는 24"x24" 두께: 1cm, 1.2cm, 1.5cm, 1.8cm, 2cm, 2.5cm, 3cm 등 |

슬래브 크기: 1800(위) x 600(위)mm 1800(위) x 700(위)mm 2400(위) x1200(위)mm 2800(위) x1500(위)mm | |

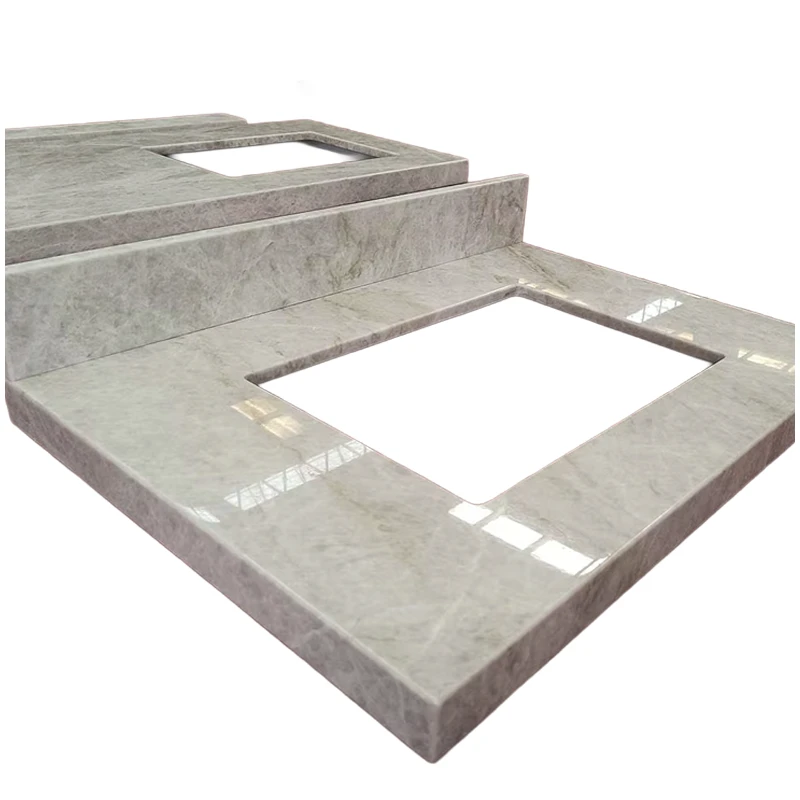

조리대: 96"x26", 98"x26", 108"x26", 76"x36" 화장대 상단: 25"x22", 31"x22", 37"x22", 49"x22", 60"x22 또는 요청에 따라. | |

표면 마감 | 광택, 연마, 화염, 분할면, 선택, 부시 망치질, 치즐, 손 절단, 샌드 블라스트, 머쉬룸, 텀블 표면. |

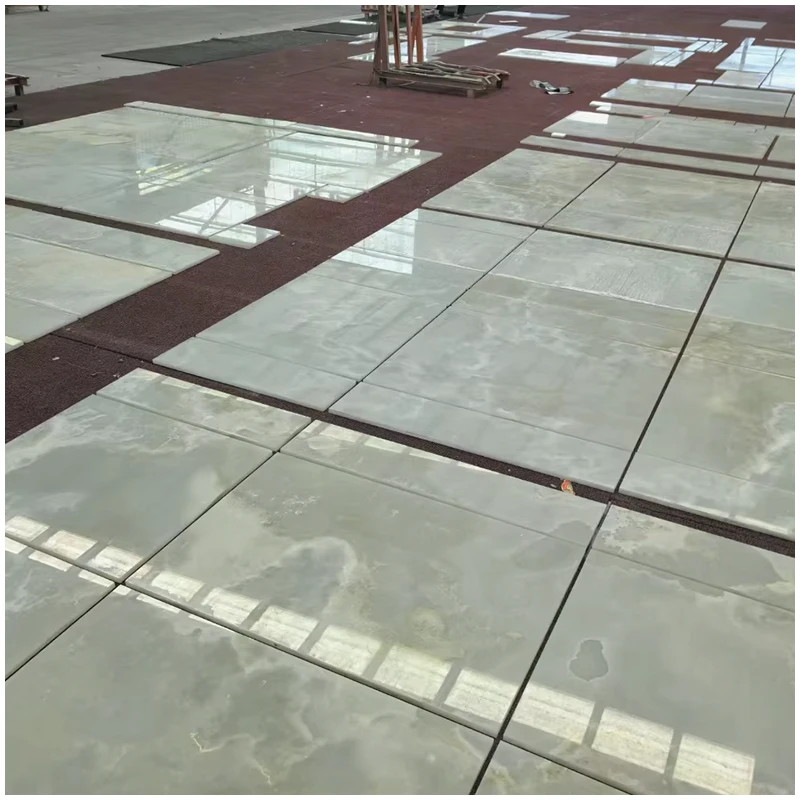

사용법 | 내부 및 외부 장식 및 건축용 벽 또는 바닥 타일, 슬래브, 상판 또는 주방 조리대를 사용할 수 있습니다. |

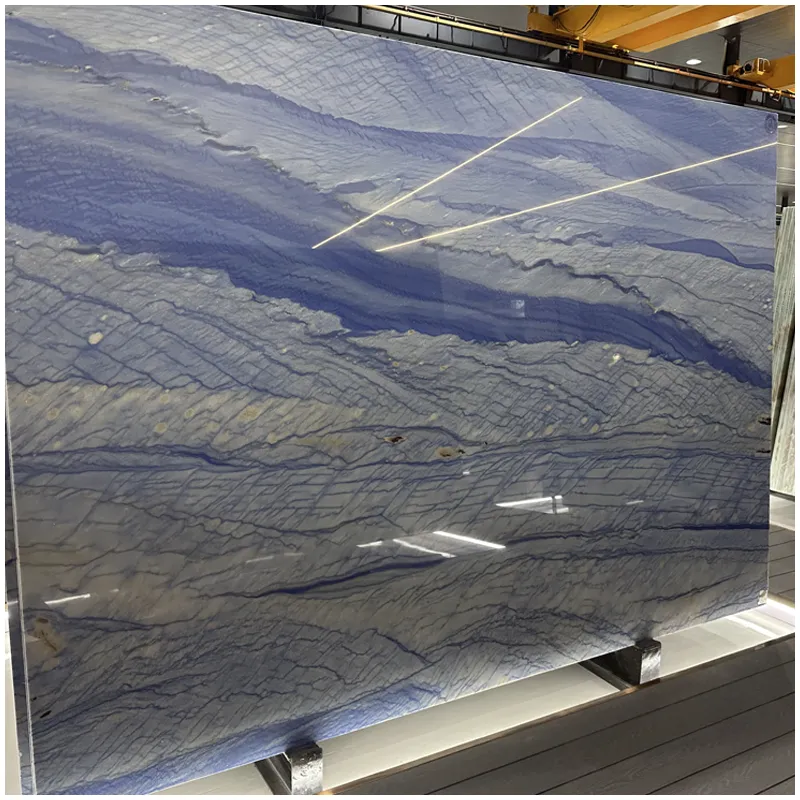

How are slabs cut?

Huge blocks of stone are excavated from the earth and hauled to manufacturing locations, where they are cut by a series of large saws. They are then finished and shipped to us by boat.

Why is there a glue-like residue on the edges of marble and granite slabs?

A coat of epoxy resin is either rolled on by hand or applied by high-tech machinery, then heated to harden. The slabs are then sent through a series of diamond and synthetic abrasive lines that remove 99% of the resin, leaving a highly polished product virtually free of defects. This enables consumers to have colors of stone not available in years past, as well as a product unmatched by man-made solid surface products.