Global Policy Landscape Reshaping the Каменные столешницы Industry

EU Carbon Policies: CBAM and ESPR

From 1 January 2025 every shipment of natural stone entering the EU must be accompanied by quarterly Carbon Border Adjustment Mechanism (CBAM) reports that detail direct, indirect and embedded emissions; full carbon pricing will apply from 2026 onward. Running in parallel, the Ecodesign for Sustainable Products Regulation (ESPR) introduces a Digital Product Passport that will follow each slab from quarry to installation, recording durability data, recycled content and repair options.

For exporters and EU‑based fabricators alike, these twin rules make cradle‑to‑grave transparency non‑negotiable for Каменные столешницы.

United States: Buy American & Silica Safety

Across the Atlantic, federally funded projects must satisfy the new 65 % domestic‑content threshold set by the Build America, Buy America Act from 1 January 2025, rising to 75 % by 2029. Meanwhile, OSHA’s national emphasis program on engineered stone is now backed by a dedicated inspection blitz aimed at reducing silicosis among countertop workers. California is going further: Senate Bill 20 (STOP Act) would outlaw dry cutting and require a licensing regime for fabrication shops by 2027. Together these measures shape how Каменные столешницы may be fabricated, specified and installed in every U.S. kitchen or bath remodel.

China’s Dual‑Carbon Certification and Export Momentum

China, home to many quarries and fabrication hubs, plans to complete a national product‑level carbon‑footprint certification scheme by the end of 2025. Export‑oriented suppliers that document low‑carbon quarrying and renewable‑energy polishing lines will gain faster customs clearance and preferred treatment under free‑trade agreements—vital intelligence for importers selecting partners for high‑volume Каменные столешницы programs.

Material Focus: Granite Countertops, Marble Countertops and Beyond

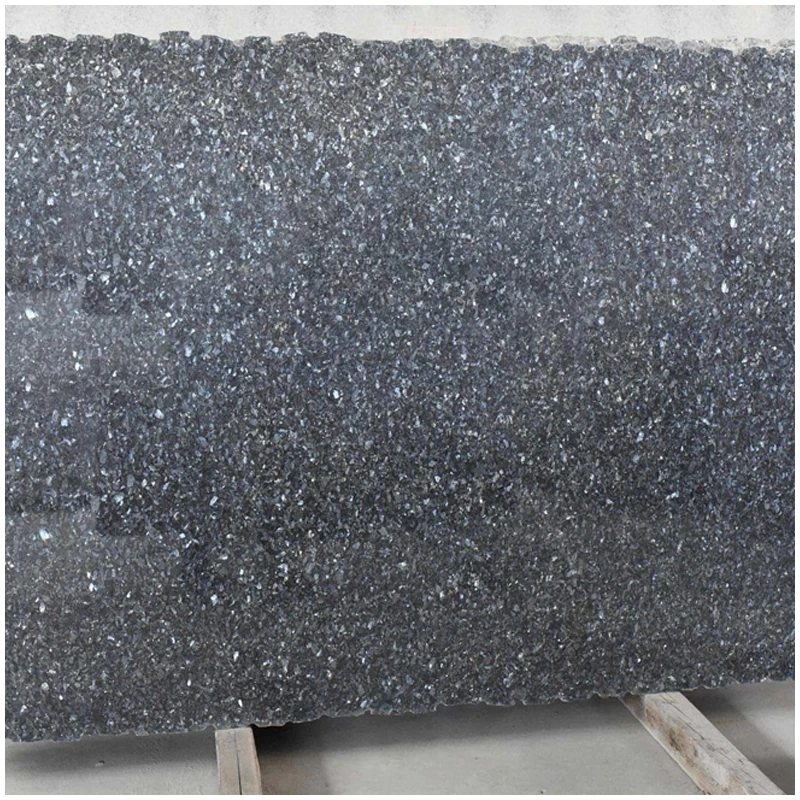

Granite Countertops: Durability Meets Low‑Carbon Sourcing

Granite Countertops remain the benchmark for scratch resistance and thermal stability, yet quarry‑to‑gate emissions vary sharply. CBAM‑ready suppliers map blast energy, haulage distance and resin content to produce Environmental Product Declarations (EPDs) that lower the declared carbon intensities now scrutinized by architects. Innovators are also replacing diesel quarry equipment with electric excavators—an easy win under ESPR scoring.

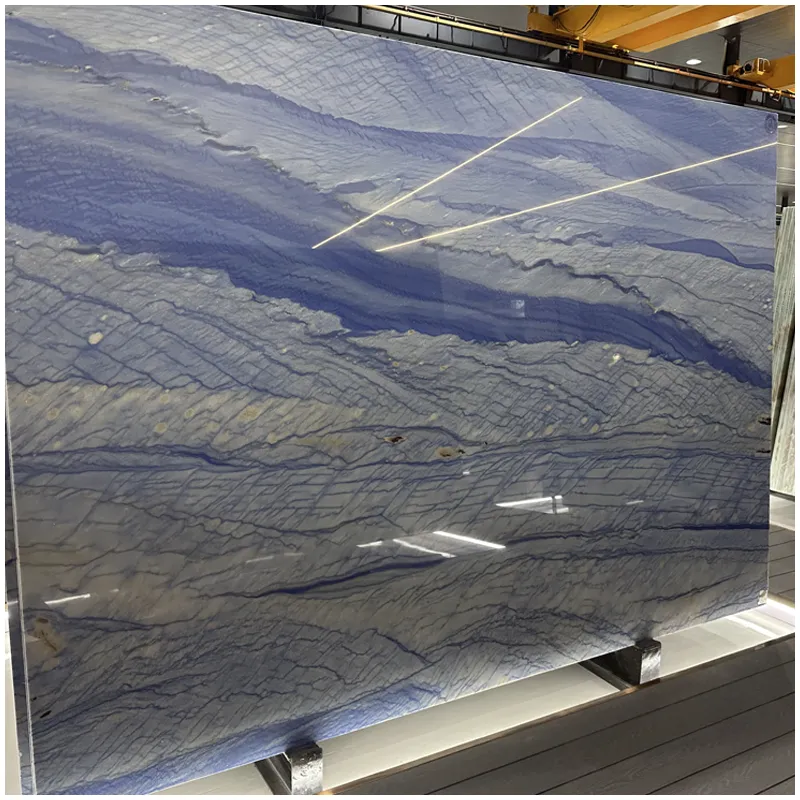

Marble Countertops and ESPR Digital Product Passports

Marble Countertops occupy a premium niche where provenance storytelling matters. Under ESPR the Digital Product Passport can certify that Carrara or Vermont мрамор carries biodiverse quarry‑restoration plans and worker‑safety audits. Designers benefit by scanning QR codes to retrieve maintenance tips or end‑of‑life recycling pathways—critical for LEED v5 material‑circularity points and for policy‑aligned Каменные столешницы branding.

Sustainable Innovations in Engineered Stone

Australia’s 2024 national prohibition on high‑silica engineered stone has triggered a pivot toward low‑silica composites, cement‑free terrazzo and sintered surfaces. Although the U.S. has not banned quartz, OSHA and California’s STOP Act effectively require wet fabrication, HEPA extraction and medical surveillance. Suppliers able to offer ≤40 % crystalline silica formulations provide insurers and developers a path to comply without abandoning the visual aesthetic that homeowners still associate with contemporary Каменные столешницы.

Application Insights: Kitchen Countertops and Bathroom Vanity Tops Under New Rules

Kitchen Countertops: Designing for Longevity and Carbon Transparency

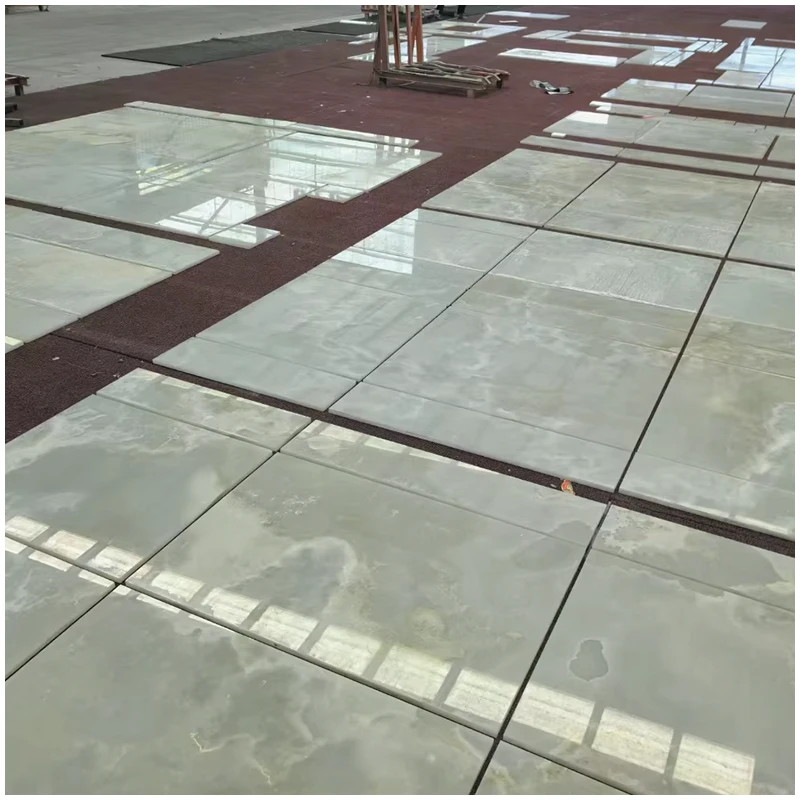

Kitchen Countertops sit at the intersection of food‑safety, heat resistance and now carbon disclosure. EU food‑contact directives already limit resin migration; ESPR adds reparability and recyclability metrics. Specifiers are therefore favoring large‑format 20 mm slabs (fewer seams, less adhesive), reversible edge profiles, and under‑mount sink cut‑outs pre‑sealed at the factory to minimize on‑site dust in line with OSHA guidance.

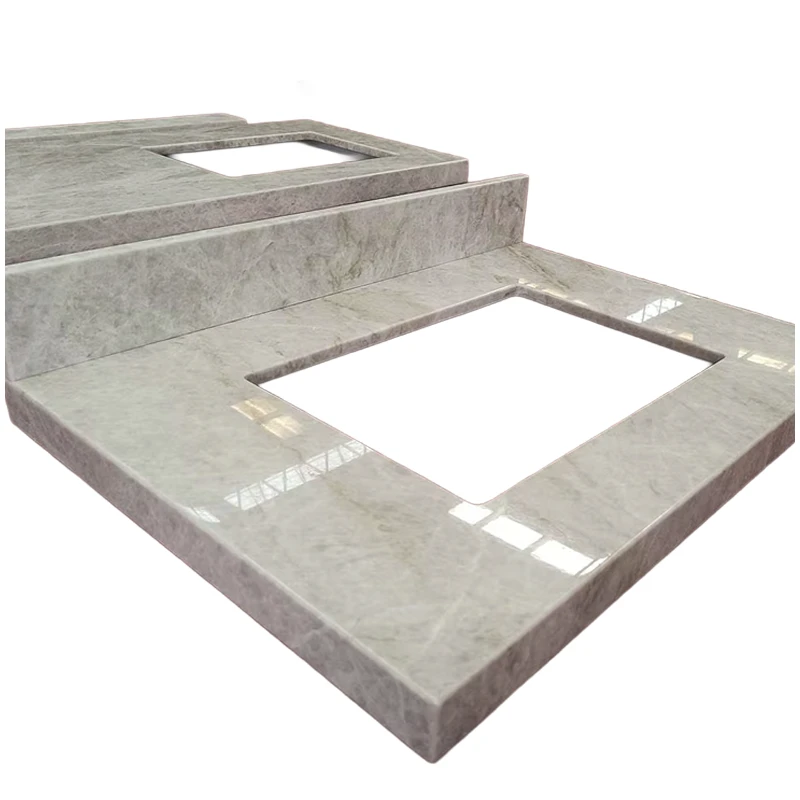

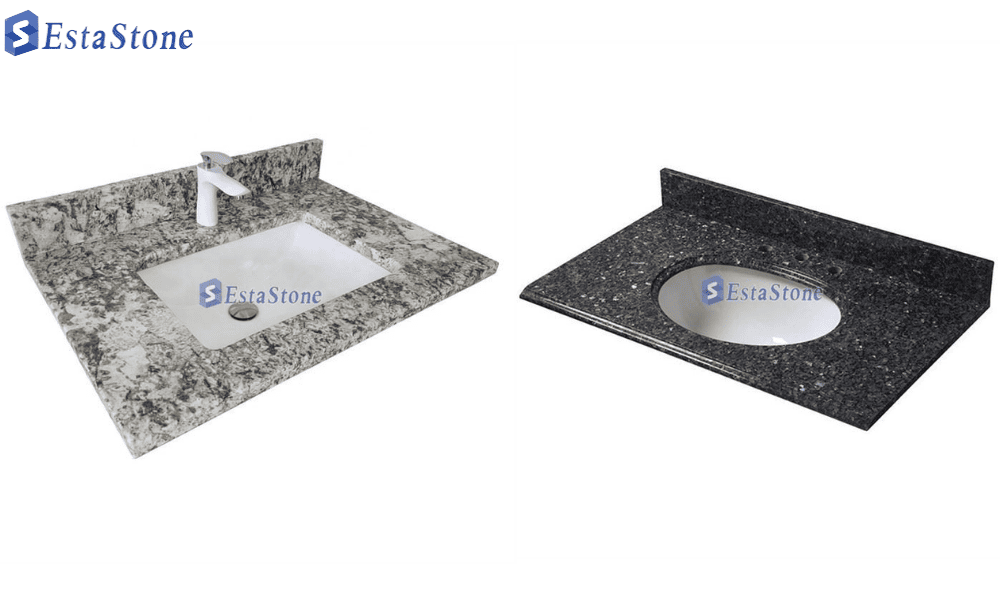

Bathroom Vanity Tops: Water Stewardship and Circular Principles

Bathroom Vanity Tops must cope with detergents and fluctuating humidity. To meet CBAM Scope‑3 expectations, forward‑looking quarries reclaim process water, while fabricators capture slurry fines for reuse as cementitious filler in shower‑tray molds. The result is a closed‑loop offering that not only wins points under WELL Building Standard v3 but also future‑proofs these Каменные столешницы against stricter resource‑efficiency targets.

Compliance Playbook for Exporters and Specifiers

Carbon Accounting and CBAM Readiness

Map emissions: pair quarry energy logs with transport distances.

Verify data: ISO 14067 or EN 15804 LCA datasets align with CBAM annexes.

Report: use the EU’s CBAM Transitional Registry for each quarter of 2025.

Meeting 65 % Domestic Content in U.S. Projects

Importers targeting federal contracts should:

Blend domestic finishing with imported blocks to lift U.S.‑cost share.

Use traceability software that attaches invoices to each pallet ID—auditors routinely sample three invoices per project under the new rule.

Safe Fabrication: Silica Mitigation Strategies

Adopt wet saws and negative‑pressure booths before OSHA inspectors arrive.

Enroll shop leads in California’s forthcoming 40‑hour silica‑safety curriculum to secure STOP Act certification early.

These measures reduce liability while keeping Каменные столешницы production lines running smoothly.

How whitemarblegranite Leads the Way

At whitemarblegranite we have already:

Achieved third‑party‑verified product‑carbon‑footprint labels for all Marble Countertops and Granite Countertops exported to the EU, aligning with CBAM methodology.

Implemented ESPR‑ready Digital Product Passports that record quarry GPS, water‑recycling ratios and recommended repair kits—ideal for modular Kitchen Countertops and Bathroom Vanity Tops.

Converted 80 % of our saw lines to wet cutting with closed‑loop recycling, surpassing OSHA flow‑rate benchmarks and positioning our U.S. distributors for seamless STOP Act compliance.

Established a North‑American finishing hub to meet Buy American’s 65 % content rule while shortening lead times by 30 %.

These initiatives make our Каменные столешницы portfolio a low‑risk, policy‑ready choice for architects, retailers and procurement officers across three continents.

The 2025 policy cycle transforms natural‑stone sourcing from a design‑driven decision into a compliance‑critical one. CBAM quantifies cradle‑to‑gate emissions; ESPR digitizes provenance; the Buy American Act rewrites cost equations; and silica‑safety legislation forces fabrication upgrades. None of these measures singles out a specific nation for censure, yet collectively they raise the bar for every actor in the Каменные столешницы value chain.

For project owners the safest route is to specify suppliers whose carbon data, safety protocols and domestic‑content strategies are already documented. For fabricators the imperative is to adopt wet methods, HEPA filtration and real‑time dust monitors before regulators arrive. And for exporters the lesson is clear: invest in verifiable carbon footprints, transparent Digital Product Passports and geographically diversified finishing.

whitemarblegranite embraces these shifts not as hurdles but as catalysts for innovation. By integrating renewable energy at the quarry, automating LCA reporting, and building a policy‑compliant North‑American finishing hub, we deliver Granite Countertops, Marble Countertops, Kitchen Countertops and Bathroom Vanity Tops that meet the highest expectations of beauty, durability and regulatory assurance.

In doing so we help designers unlock credits in LEED, BREEAM and WELL while giving homeowners surfaces that stay timelessly elegant—proof that the new rules governing Каменные столешницы can serve both the planet and the people who gather around them.