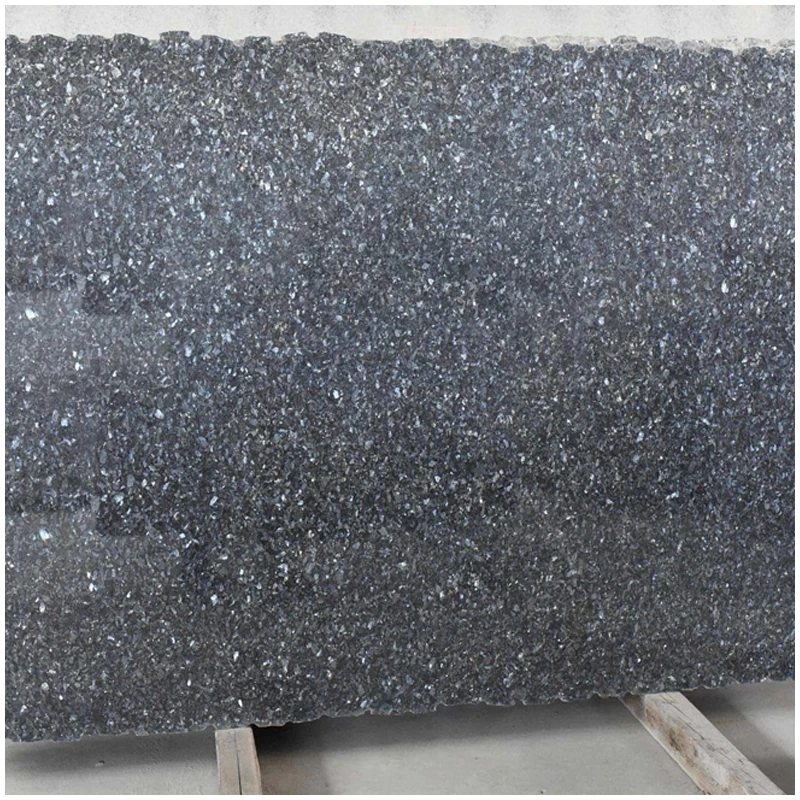

We have a dedicated product research and development department to continuously improve the products produced, so that our Black Mist Granite Floor Tiles, Black Slate Garden Slabs, Silver Travertine Stone is always at the advanced level. In terms of enhancing international influence, we actively strengthen personnel training and exchange as well as equipment and facility trade. Our successful experience in marketing includes expanding sales, strengthening market share, strengthening brand image and increasing sales volume. In the process of brand innovation and design, we learn from the world’s advanced technical experience and try our best to give customers the perfect choice. Our company is committed to sustainable development strategy, and we vigorously promote scientific and technological innovation and management innovation.

Calacatta Sintered Stone Kitchen Countertops and Bathroom Vanity Top

The Sintered Stone is made of 100% natural mineral raw materials, high-pressure pressed with a press of more than 10000 tons, combined with advanced technology, and formed at a high temperature of more than 1200 ℃ in a fully automatic furnace with strict temperature control. The harsh manufacturing environment has created the super performance of the rock board. The use environment like the kitchen can easily cope with the rock board table. In the decoration design, the rock board is the most advanced and influential safety and environmental protection material, leading a high-quality life.

Sintered Surface Countertops is a very durable and stain-resistant Kitchen and Bathroom material or can be used in commercial and residential applications.

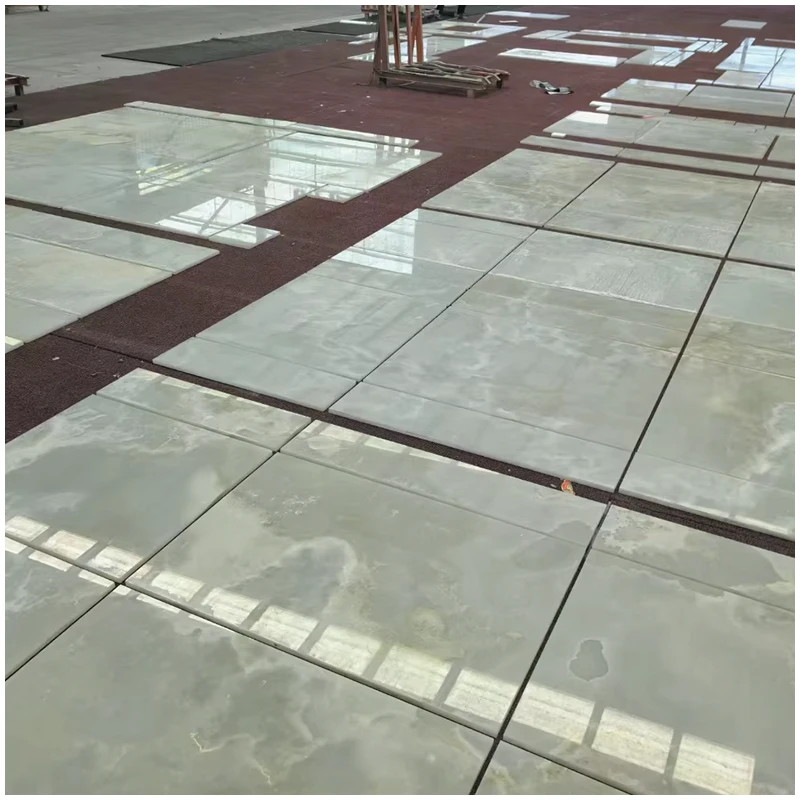

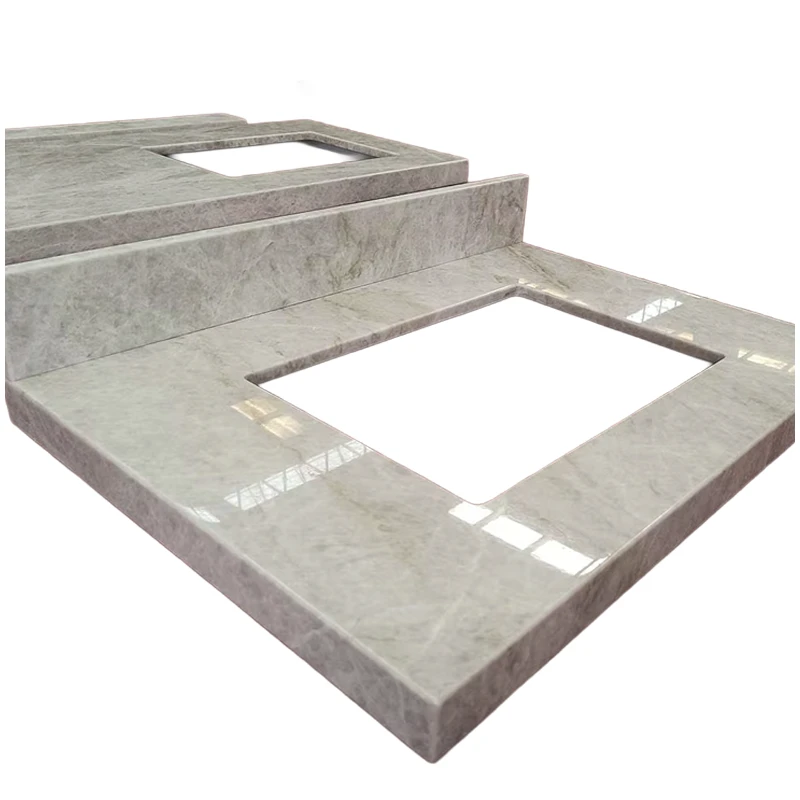

Fabricated Calacatta Sintered Stone Countertops in Private Home, it's almost the same as natural Calcatta Marble.

Fabricated Calacatta Sintered Stone Countertops in Private Home, it's almost the same as natural Calcatta Marble.

The precision original pattern scanning acquisition technology and high-definition ink-jet technology can highly restore the natural color and texture of stone, form the whole body effect, achieve elegance, contain the breath of nature, make the kitchen design more noble artistic temperament, higher than marble. Sintered Surface Countertops are a common choice when it comes to kitchen and bathroom household matter as well as backsplashes and other kitchen finishes.

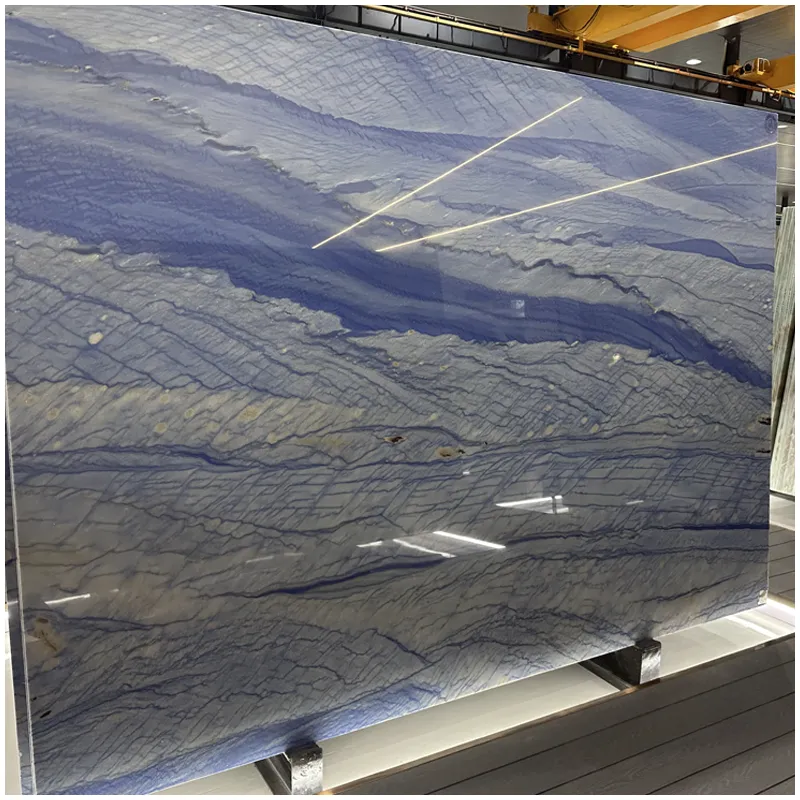

Sintered Stone Slabs can have a Large size 1600×3200, 1600×2400 mm, thickness 6mm, or 12mm. Calacatta, Statuario, Pure White, Pure grey, Pure black slabs etc. are available.

Calacatta White Sintered with Common Sizes : Slab . Size: 1800(up) x 600(up)mm. 2400(up) x 1200(up)mm. 2800(up) x 1500(up)mm etc. Thk: 15mm, 18mm, 20mm, 25mm, 30mm, etc . Tiles : Size. 305 x 305mm or 12” x 12” 400 x 400mm or 16” x 16” 457 x 457mm or 18” x 18” 600 x 600mm or 24” x 24” etc. Thk: 10mm,12mm,15mm,18mm,20mm,25mm, etc.

Quick Details | |||

Warranty: | NONE | Stone Name: | Calacatta Sintered Stone |

After-sale Service: | Online technical support | Type: | Sintered Stone |

Project Solution Capability: | Others | Material: | Engineer Sintered Stone |

Place of Origin: | China | color: | Black |

Brand Name: | Esta Stone | Size: | Customized Size |

Model Number: | White Calacatta Sintered Stone | Finished: | Polished |

Application: | Interior Tiles, Countertops | Thickness: | 10mm-30mm |

Marble Type: | Artificial Stone | price: | competitive |

Stone Form: | Sintered Kitchen Countertop and Vanity Tops | Quality: | Superior |

Product Name | Hote Sale White Calacatta Sintered Stone 9mm Kitchen Countertops | ||

Common Sizes | Slab | Size | 1800(up) x 600(up)mm |

Thk | 15mm, 18mm, 20mm, 25mm, 30mm, etc | ||

Tiles | Size | 305 x 305mm or 12" x 12" | |

Thk | 10mm,12mm,15mm,18mm,20mm,25mm, etc | ||

Countertops | Size | 96" x 26",76"x36", 98"x26", 108" x 26" | |

Thk | 3/4", 3/8", 1/2" | ||

Vanity Tops | Size | 25"x22" , 31"x22", 37"x22" , 49"x22",60" x22" | |

Thk | 3/4", 3/8", 1/2" | ||

Material | Sintered Stone | ||

Color | White | ||

Surface Finish | Polished,Honed, Antique,Acid-wash, Water-repellent, Flamed,etc. | ||

Thickness Tolerance | ±1mm | Price | EXW,FOB,CNF,Negotiation |

Usage | Indoor&outdoor | Port | Xiamen port |

Q1: What is Sintered Stone?

A: Sintered stone is a stone-based surface material that is often made to look like other materials. It can be made to resemble natural stones, tiles, wood, and other smooth or textured surfaces.

Also, it can be made to be a variety of colors, textures, and sizes. And, it’s almost always lighter than other materials, too. Sintered stone usually weighs around 1.1 – 1.5 pounds per square foot. This makes it very light yet durable.

You may see the stone as kitchen counters, vanities, stairs, and flooring. It can also provide surfaces for massive areas like outdoor flooring, swimming pools, and at spas.

Q2: How is Sintered Stone Manufactured?

A: The manufacturing process mimics the way natural stones are made, but it doesn’t take thousands of years! Rather, with modern technology, sintered stone can be put together far more quickly.

To make it, workers take stone particles and introduce them to heat and pressure that mimic what happens in the earth; the result is man-made stone, and the previous particles are bonded together permanently.

Particles are chosen based on what the finished product will look like. The color and quality of the particles are tested and then sent to become the final product. Next, workers take their time to make precise cuts into the material. Cutting is the longest part of the process, but the part that costs the most is messed up.

Indeed, the stone can get heavy and it is hard to cut, so it makes it difficult to cut off excess at the project site. This is also why you’ll normally need to go with professional installation.

We can enhance the core competitiveness of our enterprise by effectively improving the added value of our Artificial Rock Plate/ Sintered Stone Calacatta White Slab for Wall, Floor and Countertops. We insist on people-oriented, attracting and retaining talents with a friendly cultural atmosphere, and comprehensively building a series of talent echelon of R&D, technology, management and marketing to achieve sustainable development of the enterprise. We have established and improved the quality management system, so that each link affecting product quality has been effectively controlled.